Selecting the right beam trolley for your specific application is crucial for ensuring safety and efficiency during lifting operations. As a leading lifting equipment hire company, LGH UK is committed to providing customers with the best beam trolley solutions for their needs. In this comprehensive guide, we will discuss different types of beam trolleys, their safe use, maintenance, and why LGH UK stands out as an expert in the industry.

What is the purpose of a Beam Trolley?

A beam trolley is an essential tool for lifting and suspending equipment like hoists in various settings, such as warehouses, construction sites, and workshops. It provides a movable anchor point on a steel beam, streamlining load transportation and enhancing safety by allowing hoists to move efficiently up and down the beam.

Types of Trolleys

Push Trolleys

Push travel beam trolleys are manually operated and attach to the lower flange of a flat or tapered beam. Equipped with wheels for easy manoeuvring, they support a manual chain hoist with a top hook and are best suited for lighter loads. LGH UK offers push trolleys with a working load limit (WLL) of 1t-10t.

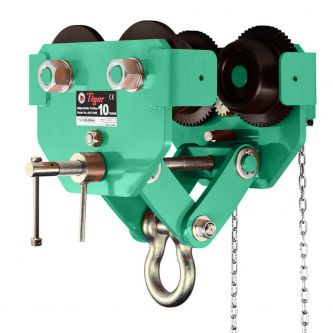

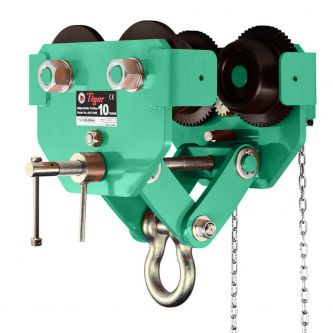

Geared Trolley

Ideal for accurate placement of heavier loads with great variability of size and capacities, geared trolleys feature a looped hand chain connected to a sprocket. Pulling the chain moves the trolley across the beam. They are ideal for heavy loads where no power source is available. LGH UK's range of geared trolleys includes adjustable and twin bar models, with WLLs from 0.5t-30t.

Air Powered Trolley

Designed for heavy weights with a WLL of 10t-25t, air-powered trolleys are easy to install and can negotiate curves.

Safe Use of Beam Trolleys

Proper handling and usage of beam trolleys are essential for their longevity and optimal performance. Follow these dos and don'ts for safe operation:

Do:

- Handle with care, avoiding drops and impacts.

- Store in a clean, dry area.

- Inspect and test before and after each use.

- Ensure the wheel profile and width are suitable for the beam.

- Confirm that the trolley, beam, and hoist are suitable for the load.

- Lock the adjustment bar before every use.

- Clean the beam of debris and obstructions.

Don't:

- Expose to corrosive chemicals, water, or steam without verifying suitability.

- Force the hook onto the load bar.

- Throw or drop the trolley.

- Use a damaged trolley.

- Side-load a trolley.

- Use a trolley on an unsuitable beam.

- Make modifications to the trolley.

Maintaining and Inspecting Beam Trolleys with LGH UK

When you hire from LGH UK, you can trust that our workshop engineers regularly test and maintain all equipment in our fleet. Before each hire, our beam trolleys undergo a thorough examination, including checks for:

- Clearly marked WLL and ID number.

- Component condition (side plates, gears, suspension shackle, etc.).

- Proper chain positioning in the sprocket.

- Damage-free locking device with unworn threads and a straight bar.

Installation Tips

Refer to the manufacturer's document for instructions on installing your beam trolley, and consider the following tips:

- Ensure the track is level with an even surface.

- Verify beam end stops are in place.

- Check that wheels are suitable for the track.

- Set the trolley to the width of the beam and secure it firmly.

- Attach end stops and tighten all nuts and bolts.

Routine Maintenance

To keep your trolley in optimal working condition:

- Lubricate all moving parts regularly.

- Clean the wheels and track to remove debris or lubricant.

- Conduct regular inspections to identify damage, loose fittings or faults.

Why Choose LGH UK for Your Beam Trolley Needs?

LGH UK boasts an extensive hire fleet, featuring a wide range of beam trolleys suitable for various applications and available for next day collection and delivery. With over 50 years of experience, LGH UK has become the leading organisation dedicated exclusively to the hire and sale of lifting and moving equipment.

Our team of lifting experts can guide you in selecting the right beam trolley for your needs and provide ongoing support throughout your project. For professional assistance and top-quality equipment, look no further than LGH UK.

Contact our expert team on 03704 247 247 or email us at enquiries@lgh.co.uk. You can also complete the Contact Us form or alternatively use our chat box and we'll get back to you as soon as possible.