What Is A Shackle?

Also known as D-links, shackles are u-shaped load bearing devices with a removable pin. They are used between loads being lifted and load lifting devices such as chains, slings and wire ropes.

What Are Shackles Used For?

There is a range of uses for shackles, the most common being:

• Winching

• Hoisting

• Lifting

• Rigging

• Pulling

Like all lifting equipment, it’s important to know exactly what type of shackle to use to avoid a lifting failure. The most important thing to know about your shackle is whether its SWL (Safe Working Load) matches or exceeds the weight of the load you intend to lift and the additional lifting equipment being used.

The wide range of designs and functions can make it difficult to know the right shackle for your requirements, so let’s break down the differences.

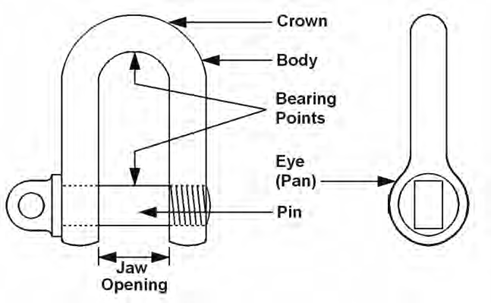

The Different Parts of a Shackle

We can’t discuss shackles until we know what each part is and what it does:

• Pin – The bolt that connects the ears and seals off the bow.

• Eye (Pan) – Attaches and supports the pin.

• Crown/Bow/Body – The main body of the shackle, comes in varying shapes (more on that later).

• Pinhead/Shoulder – Part of the pin that is against the ear when pin is in use.

Image Source: LEEA

Different Shackle Shapes & Their Uses

The selection of the shape of the shackle body will depend on the intended use. They are both suitable for use with hook eyes, eyebolts, egg links, wire rope thimbles, etc. and for the head fittings of ships’ blocks. The bow shackle can also be used for the body of hooks.

Anchor/Bow Shackles

The rounded shaped shackles are referred to as Bow or Anchor shackles. Their shape means that they can be side loaded as they are less likely to twist and they can be used to attach multiple connections.

They are, in general, used where more than one attachment is to be made to the body or to to allow freedom of movement in the plane of the bow.

Chain / Dee Shackles

Most commonly known as D shackles because of their shape, Chain shackles are narrower than their counterparts. Unlike bow shackles they are not to be side loaded as their shape makes them susceptible to twisting and they are instead designed for in-line tension. In general, they are used to connect two pieces of lifting equipment together in a straight line, where the load line is centred to the centre line of the shackle.

Types of Shackle Pin

As important as the shape of the bow is the type of pin you’re using. Some pins are designed for long term use, others may loosen over time and are best used for lifting projects where you will connect and disconnect new items frequently.

Screw Pin

Named because they screw into the body of the shackle, a screw pin connects the two ears and is threaded at one end so it can be tightened and sealed securely. This means that you can attach and detach the pin and rigging equipment with ease, but they are prone to coming undone due to vibration and movement and so aren’t recommended for permanent use.

One way to combat this potential lifting failure is called mousing, this is where iron wire is put through the hole in the pin and secured around the shackle so that the pin is unable to move out of the ear/lugs.

It’s important to fully screw the pin into the shackle and ensure that the shoulder is firmly in contact with the ears before each lift.

Bolt Pin

More secure than a screw pin, bolt pins use a nut, bolt and cotter pin to secure between the ears. Thanks to this, it is less likely to accidentally open and cause a lifting failure. Bolt pins can be used for the same projects as a screw pin as well as semi-permanent and long term installations. The secure design means they do not need to be repeatedly tightened or checked for unthreading.

Round Pin

They key difference between the round pin and the others is that it is unthreaded and secured only by a cotter pin. As such, they are perfect to be used in situations where they may experience twisting from the forces of the rope.

Most commonly used in pulling, towing or tie-down applications, round pin shackles are not intended for use in overhead lifting or connecting multiple slings.

Servicing & Maintenance

The most time consuming and expensive part of owning equipment is maintenance. Before and after each use inspect your shackles for damage, it is not only when in use that you need to take care of your shackles. They need to be stored, serviced and maintained correctly to ensure they function as intended. At LGH we routinely inspect and service our shackles meaning you don’t have to, saving you time and money.

Hire a shackle today

LGH have got a large, varied range of high quality GreenPin shackles with capacities starting from 0.5t up to 400t.

Contact one of our lifting experts and see how we can help you with your lifting needs on 03704 247 247 or enquiries@lgh.co.uk.