The Importance of Accurate Load Measurement and Monitoring in Lifting and Rigging

If you're in the business of lifting and rigging, you know the importance of accuracy and safety. To achieve both, you need the right equipment. Two pieces of equipment commonly used for load measurement and monitoring are Loadlinks, also known as Radiolinks or Digital Load Indicators, and Loadshackles. While the usability of Compression Load Cells to weigh a static load is quite straightforward, the use of Loadlinks and Loadshackles is a little more complicated. Let’s explore what they are, their differences and similarities, and how LGH UK's fleet will help you get the job done safely.

Differences and Similarities

The key difference between Loadlinks and Loadshackles is their purpose. Loadlinks are used for load measurement, while Loadshackles are used for load monitoring. However, they have some similarities.

Both Loadlinks and Loadshackles are highly accurate and can provide real-time data on the load being lifted. They are also designed to be durable and can withstand harsh environments, making them ideal for use in the lifting and rigging industry.

What are Loadlinks and Loadshackles?

Loadlinks and Loadshackles are both designed to be part of the rigging process. They act as connectors between the load and the lifting equipment and provide real-time information about the forces being exerted. However, their purposes are different.

Loadlinks

Loadlinks are used for load measurement, meaning they measure the weight of the load being lifted. They come in various sizes and capacities, with LGH UK’s fleet ranging from 5t – 250t, and can be used with a range of lifting equipment, including cranes, hoists, and winches. Loadlinks are highly accurate providing real-time data to ±0.1% accuracy to ensure safe lifting.

Loadshackles

Loadshackles are used to monitor the load and prevent overloading. They are made from a standard shackle that has been modified by fitting strain gauges through the center of the pin, turning it into a Loadpin.

Loadshackles are ideal for applications where the weight of the load is unknown, or the load is subject to dynamic forces. They provide real-time data on the load, allowing the operator to monitor and adjust the lifting process as necessary. They are not as accurate as Loadlinks with ± 1% accuracy.

Loadlink

How Do Loadlinks & Loadshackles Work?

To understand why Loadlinks are used for load measurement, and Loadshackles are used for load monitoring, you need to understand how they work.

Loadlinks

Loadlinks use a strain gauge, which is a device that measures the strain or deformation of an object. When a load is applied to the Loadlink, the strain gauge measures the deformation and converts it into an electrical signal. This signal is then converted into a weight measurement, which is displayed wirelessly on a digital screen.

Loadshackles

Loadshackles, as mentioned earlier, are standard shackles that have been modified with strain gauges. When a load is applied to the Loadshackle, the strain gauges measure the deformation and converts it into an electrical signal. This signal is then sent to a remote display, allowing the operator to monitor the load in real-time.

Advantages & Disadvantages

Advantages of Loadlinks

- Highly accurate for load measurement. 3x more accurate than a Loadshackle

- Can be used with a range of lifting equipment

- Real-time data ensures safe lifting

- Can be used to calibrate devices such as Safe Load Indicators

Advantages of Loadshackles

- Can monitor load and prevent overloading

- Ideal for applications where load weight is unknown or subject to dynamic forces

- Real-time data allows for monitoring and adjustment of the lifting process

- 1/3 of the size of a Loadlink with shackles attached

- Easier handling for mobile testing

Disadvantages of Loadlinks

- Can only measure load weight, not monitor it

- May not be suitable for dynamic loads

- Headroom Loss

Disadvantages of Loadshackles

- May not be as accurate as Loadlinks for load measurement

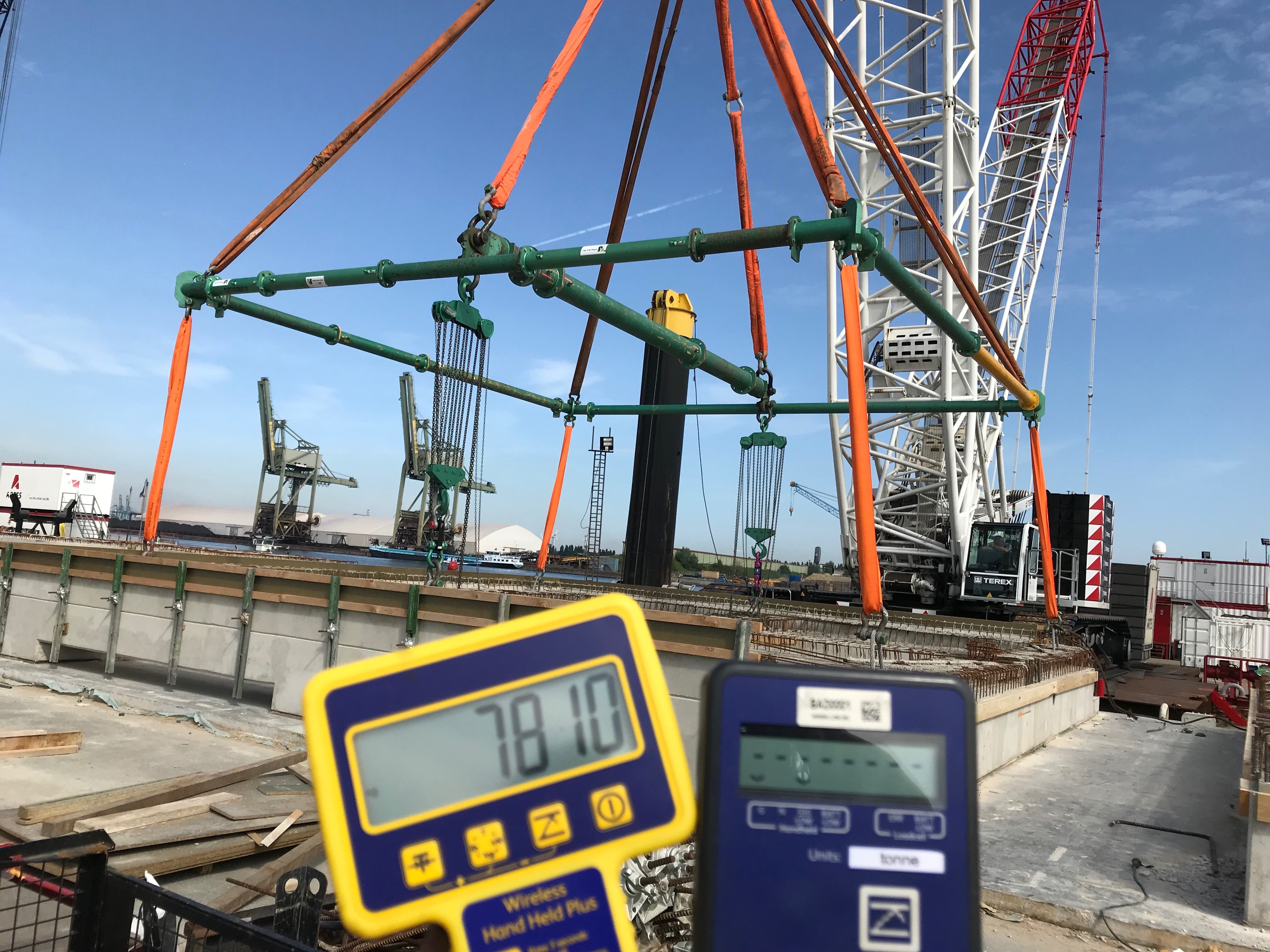

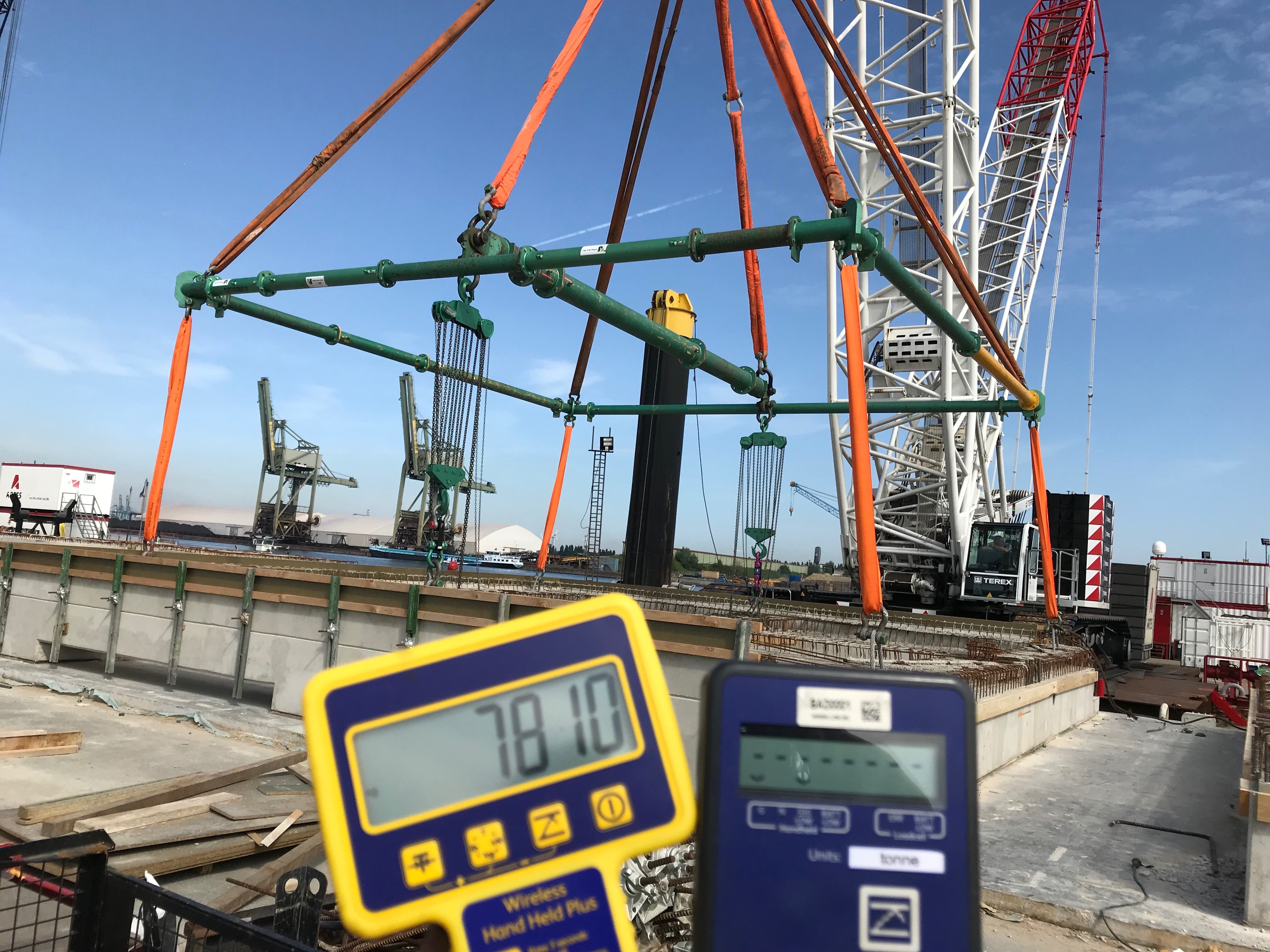

Loadlink In Rigging

Wireless Display for Loadshackles & Loadlinks

Choose LGH UK for Safe and Accurate Lifting With Loadlinks & Loadshackles

Loadlinks and Loadshackles are essential tools for accurate load measurement and monitoring in lifting and rigging projects. While they share similarities in terms of their durability and real-time data capabilities, they also have distinct differences in their purposes and accuracy. By understanding the strengths and limitations of each equipment type, you can make an informed decision on which one is best suited for your lifting project.

At LGH UK, we understand the importance of having the right equipment for the job. That's why we offer a range of Loadlinks and Loadshackles for hire, along with a variety of other lifting and rigging equipment. Our team of experts can help you choose the right equipment for your needs and provide support throughout your project.

So whether you need to measure the weight of a load or monitor it to prevent overloading, LGH UK has you covered. Contact us today to discuss your equipment needs and learn more about how we can help you achieve safe and accurate lifting.

Loadlinks - 5t - 250t WLL

Know What You Need? Get In touch

Need to hire equipment ASAP? Call LGH UK's experts today to get the equipment you need for your project!

Planning ahead for your lifting and rigging project? Send us an email to discuss your needs.

Why Choose LGH UK?

LGH UK's hire fleet includes Straightpoint Loadlinks with WLL's from 5t - 250t, suitable for all your lifting and rigging needs and available for next day collection and delivery. Whether you need to measure the weight of a load or monitor the load to prevent overloading, LGH UK has the equipment and expertise to assist you.

In addition to Loadlinks, LGH UK's hire fleet includes a range of lifting and rigging equipment, including hoists, winches, jacks, and more. Their team of experts can help you choose the right equipment for your needs and provide support throughout your project. Speak to a lifting expert today.