Choosing the right lifting sling!

Are you in the midst of planning a lifting project and feeling uncertain about which sling type to use? Perhaps you're experiencing dissatisfaction with the current slings you're using and not achieving the expected service life. It is crucial to select the appropriate lifting sling as part of your lift plan.

Various types of slings, such as web slings, wire rope slings, polyester round slings, and chain slings, can all be employed to safely and efficiently lift, move, and position loads. However, the choice of the right sling relies on factors like understanding the lifting application, the lift's environment, and how the sling will be employed to support and lift the load.

While this article does not aim to provide a comprehensive guide, our objective is to present you with a broad overview of the diverse sling types available from LGH. We will outline the advantages and disadvantages of each type, empowering you to make a well-informed decision when selecting the most suitable sling for your specific application.

Wire Rope Slings

Wire rope slings are widely utilised in industries that encounter harsh and demanding conditions, thanks to their exceptional strength, flexibility, and resistance to abrasion. These slings boast a distinctive construction comprising multiple steel wires formed into individual strands arranged in a helical pattern around a core made of either fibre or steel.

At LGH, all wire rope slings are mechanically spliced and feature a standard eye-to-eye design. They are available in a diverse range of capacities and sizes to suit various lifting requirements.

Pros:

- Lighter in weight and lower initial cost than alloy chain slings.

- Different designs provide strength, flexibility, and abrasion/fatigue/corrosion resistance.

- Can be used in vertical, choker, and basket hitches.

- If the wire rope is damaged, the hardware may be re-used – provided it is undamaged.

Cons:

- Difficult to inspect – especially in and around the core.

- Abuse or misuse may cause kinking, crushing, or abrasion, resulting in damage and loss of strength. Unrepairable if damaged.

- Susceptible to internal and external corrosion.

- Not to be used in temperatures above 400˚F or below -40˚F.

Polyester Round Slings

Round slings are designed with load-bearing fibre or core yarns that are safeguarded by a woven outer jacket. This jacket serves as a protective layer, shielding the internal load-bearing fibres and core yarns from abrasion, dirt, grease, and the harmful effects of UV degradation.

These slings are particularly well-suited for a wide range of lifting applications in both general and heavy industrial settings. With their remarkable precision and flexibility, round slings enable efficient and safe execution of heavy lifting tasks.

Pros:

- Weighs approximately a tenth of the total weight of a comparable steel sling.

- Strong, soft, and flexible composition means the sling will not damage your load when used correctly.

- Usable in vertical, basket, or choker hitches.

- Suitable for acidic environments and around bleaching agents.

Cons:

- Susceptible to heat damage.

- Wear pads required for loads with sharp edges or in any case where extra durability is needed.

- Weakened by prolonged exposure to sunlight and UV rays.

- Not to be used in alkaline environments.

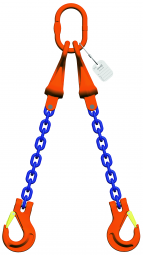

Chain Slings

When it comes to durability, chain slings stand at the forefront. These slings are specifically designed to lift heavy and bulky loads, whether on a regular or repetitive basis.

Their outstanding strength, durability, and remarkable heat resistance make them particularly suitable for usage in environments such as foundries, steel mills, heavy machine shops, and other settings where repetitive lifts or harsh conditions could cause damage or destruction to other types of slings.

Moreover, chain slings offer flexibility in their design, as they can be configured as single-leg, 2-leg, 3-leg, or 4-leg slings. By utilising various sling hooks, lengths of chain, and master links, a wide array of sling assemblies can be created to cater to diverse lifting applications.

Pros:

- If damage occurs, chain slings are repairable and can be load tested and re-certified after repair

-

Able to withstand extreme temperatures

- May be configured for use in vertical, choker, or basket hitches

- Resistant to corrosion, chemicals, and UV exposure

Unaffected by dirt, oil, or grease

Cons:

- Very heavy – the higher the rated capacity, the heavier the chain will be

- May be more expensive than other sling types

- Can easily crush or damage sensitive or finished parts

Many options are available when selecting the correct sling for your lifting application. However, various factors should be considered before sling selection to ensure the sling you choose can operate safely and efficiently for your business needs.

Get in touch with one of our lifting experts and let them help you with your next project. With over 50 years of experience, LGH are the single largest organisation dedicated exclusively to the hire and sale of lifting & moving equipment.

Call one of our specialists on 03704 247 247 or email us at enquiries@lgh.co.uk. You can also complete the Contact Us form and we'll get back to you as soon as possible.